Plant Locations

Our proudest PLANTS Thorough commitment to quality, safety, and the environment. Yushiro is proud of its production bases.

Many of Yushiro's high-quality products that earn the trust of our customers are produced at these two production bases, which are equipped with advanced facilities.

In addition to an excellent quality management system certified to ISO 9001, Yushiro is thoroughly committed to ensuring safety and reducing environmental impact.

In particular, as the pillar of our environmental measures, we have established an environmental management system, which acquired ISO14001 certification. We are conducting ideal production activities based on ""harmony with the global environment and local communities"", including cost reductions based on resource and energy conservation.

Quality Policy

Establish an appropriate level of QMS certified to ISO 9001 and continuously improve its effectiveness.

Strive to improve customer satisfaction and earn the lasting trust of our customers.

Set quality goals, review them regularly, and strive for continuous improvement.

Strive to reduce all nonconformities that occur in the plants.

Ensure that this quality policy is communicated and understood by all levels in the factories.

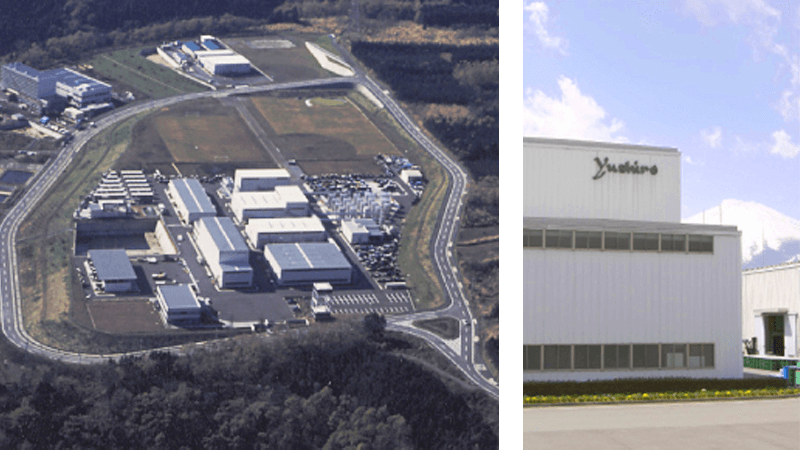

Fuji Plant Fuji Plant

Fuji Plant is a high-value-added plant for manufacturing high-quality products based on the concept of "achievement of comfort and affluence". Located in a scenic area of lush greenery at the foot of Mount Fuji, Fuji Plant is the equal of the Hyogo Plant, which covers western Japan. It supplies many products not only to users in eastern Japan but also to overseas markets.

Facility Building Outline

-

Completion: June 1, 1992

-

Site area: 76,917 m2

-

Building area: 6,972 m2

-

Production capacity: 4,500 kL/month

Certification Body, etc.

Registered Business: Fuji Plant of Yushiro Inc.

Certification Body: Japan Quality Assurance Organization

Registration Certificate Number: JQA-1450

Date of Registration: November 8, 1996

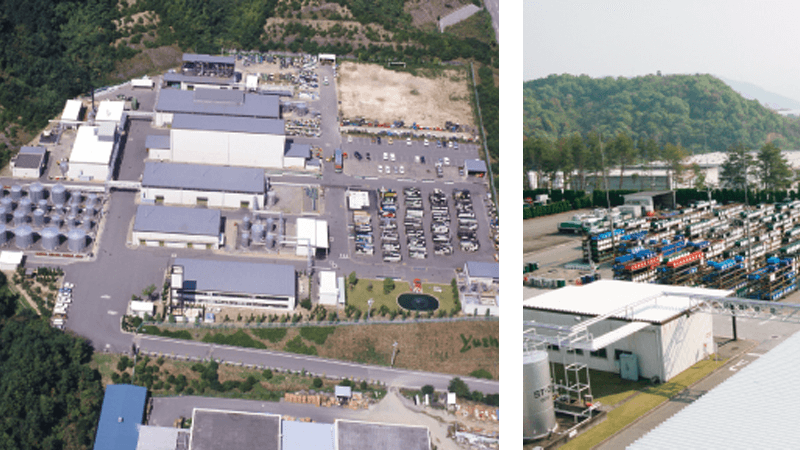

Hyogo plant Hyogo Plant

The concept of Hyogo Plant is "safety, comfort, and efficient and stable production of high quality products." Located in the northern part of Himeji City, which is famous for White Heron Castle (Himeji Castle), Hyogo Plant ships high-quality products mainly to users in western Japan, while Fuji Plant covers eastern Japan. Today, it exports and supplies many products overseas as well.

Facility Building Outline

-

Completion: June 2, 1980

-

Site area: 39,500 m2

-

Building area: 5,497 m2

-

Production capacity: 4,000 kL/month

Certification Body, etc.

Registered Business: Hyogo Plant of Yushiro Inc.

Certification Body: Japan Quality Assurance Organization

Registration Certificate Number: JQA-1953

Date of Registration: November 7, 1997

OFUNA Plant OFUNA Plant

OFUNA Plant is a facility that embodies the concepts of "reliability and technical service." Located in Kamakura, this plant specializes in various fields of surface chemical treatment, where we conduct the development, manufacturing, and management of chemicals within the facility. We export and supply a wide range of products from this plant to various locations nationwide and overseas.

Facility Building Outline

-

Completion: August 23, 1960

-

Site area: 5,622 square meters

-

Building area: 2,113 square meters

-

Production capacity: 3,000 tons per year, 250 tons per month

Certification Body, etc.

Registered Business: Ofuna Plant of Yushiro Inc.

Certification Body: ASR Co., Ltd.

Registration Certificate Number: Q1736

Date of Registration: July 31, 2000

List of manufactured products List of Products Manufactured

Metalworking oil and fluids

Cutting/Grinding Oils and Fluids

Water-miscible cutting/grinding oils

Water-immiscible cutting/grinding oils

Plastic Working Oils and Fluids

Water-miscible rolling oils

Water-immiscible rolling oils

Hot rolling oils for seamless pipes

Graphite-free hot forging oils

Drawing/pressing oils, cold forging oils

Surface Treatment Agents

Rust-preventive oils

Cleaning agents

Oils for Cutting Silicon, Quartz, Ceramics, etc.

Water-miscible oils for inner blades

Water-immiscible slurry bases for blade saws

Water-immiscible slurry bases for wire saws

Non-flammable water-immiscible slurry bases for blade saws

Water-miscible slurry bases for wire saws

Mold Release Agents

Mold release agents for aluminum die casting

Mold release agents for magnesium die casting

Mold release agent for urethane foam

Plunger lubricants

Water-Soluble Quenching Liquids

Flame-Retardant Hydraulic Fluids

Others

Grinding oils for glass

Products for building maintenance

Floor Polishes

Urethane resin waxes

Acrylic resin waxes

Floor Cleaners

Surface cleaners

Peeling agents

Floor detergents

Carpet detergents

Soaps

Hand soaps

Deodorants

Aviation

Exterior Cleaners

Lavatory Maintenance

Paint Removal

Chemical Processing

Engine Overhaul

De-icing and Snow-Melting Agent

Precision Cleaning

Optical Cleaners and Removers

Plastic Lenses Cleaner and Removers

Removers for Nanoimprint lithography

Metal forming

Reactive Lubricants

Plastic working related cleaning agents

Non-Bonde Lubricants

Paint and Adhesion

Basis for Painting

Basis for rubber Adhesion